The Inner Shoe Primary Mechanical Shoe Seal for Internal Floating Roofs

The Mechanical Inner Shoe Seal is the most efficient option on the market for internal floating roof primary seals. Featuring robust, all stainless-steel components. This seal provides effective, tight shoe fit at both small and large annular rim gaps with a long and reliable service life.

Primary shoe seal for internal floating roof tank can be easily and safely installed during either in-service or out-of-service periods. And is suitable for almost any internal floating roof style and configuration.

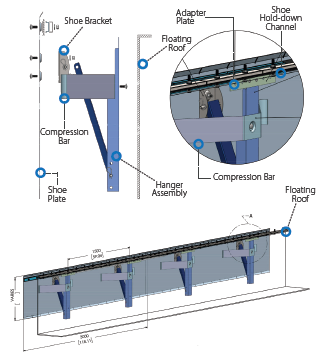

The DirecTank Inner Shoe support mechanism consists of a durable uni-pivot hinge configuration. With sufficient structural rigidity to support the shoe plate during travel within rim spaces. The shoe plate is kept in constant, tight contact with the tank shell by complementary compression elements consisting of hardened spring steel. These components allow for reliable performance. Even in the most challenging operational conditions, including small annular rim space and tank shell inconsistencies.

This inner mechanical shoe seal is the most versatile, robust primary seal option on the market providing long, reliable operation and efficiency.

Check out our Secondary Metalic Wiper Seal – Internal & External Roofs

Key Features:

- Rim mount design with uni-pivot hanger arm.

- Hardened high-tensile stainless-steel spring components

- All stainless-steel components. Stainless Steel-Aluminum is available

- Can be installed in or out-of-service

- Premium vapor barrier fabric options, including Polyurethane and Teflon

- Ideal for retrofitting to replace existing underperforming seals

- Suitable options for Steel, Aluminum, and Composite internal floating roofs

Key Benefits:

- Reliable operation in very small rim spaces

- Robust components developed to provide continuous, worry-free Operation

- Excellent Shoe Compression ensuring a Tight Fit across entire working range

- Full traceability on manufacturing and materials independently certified

- Simple, Safe Installation with all-bolted connections and no necessary hot-work

- Full compliance with all relevant codes and regulations, including the EPA 40 CFR 60 and local Air Quality Management District requirements.