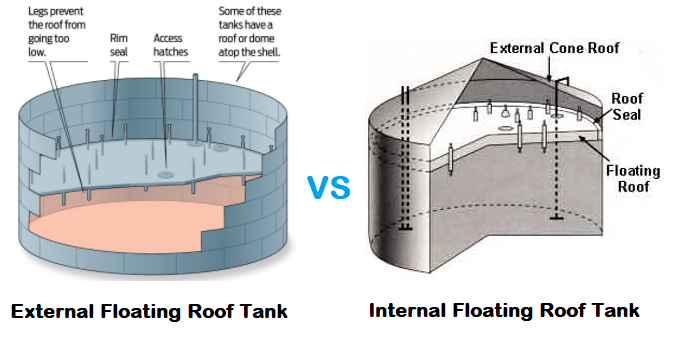

Difference between Internal and external floating roof tanks

Here you are likely familiar with the two most common types of storage tanks. Difference between Internal and external floating roofs. Used for storing crude oil, gasoline, and other petrochemical products. internal floating roof tanks and external floating roof tanks. While both types of tanks serve the same purpose of storing liquid hydrocarbons, they differ in design, construction, and operation. Here we will see key differences between tank internal floating roof and external floating roof tanks, and help you understand when one type of tank is more suitable than the other.

Internal Floating Roof Tank

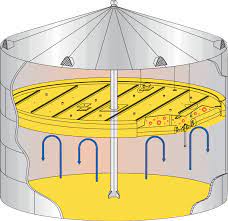

An internal floating roof tank (IFRT) is a type of storage tank that has a fixed roof and a floating roof inside the tank. The floating roof rests on the liquid surface and moves up and down as the liquid level in the tank changes. The floating roof is usually made of aluminum or stainless steel and has a floating roof seals seal that prevents vapors from escaping the tank. The roof is supported by a series of pontoons that are attached to the roof’s underside and rest on the liquid surface.

IFRTs are commonly used for storing volatile liquids, such as gasoline and jet fuel, where emissions control is a critical concern. The floating roof reduces the amount of vapor space in the tank, which in turn reduces the amount of hydrocarbon emissions that are released into the atmosphere. The internal design of the tank also minimises the risk of fire and explosion, as the floating roof acts as a barrier between the liquid and the air above.

However, IFRTs are more expensive to construct and maintain than external floating roof tanks (EFRTs) due to the added complexity of the design. The floating roof requires regular maintenance to ensure that it remains watertight, and the pontoons must be inspected and replaced periodically.

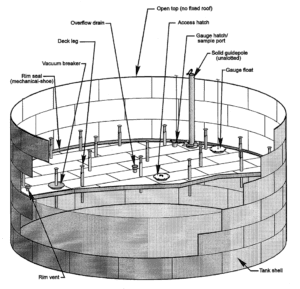

External Floating Roof Tank

An external floating roof tank (EFRT) is a type of storage tank that has a fixed roof and a floating roof that sits on top of the liquid surface. The floating roof is usually made of steel and is supported by aluminum pontoon that rest on the liquid surface. The roof has a rim seal that prevents vapours from escaping the tank, and it can be raised or lowered to accommodate changes in the liquid level.

EFRTs are commonly used for storing non-volatile liquids, such as crude oil and diesel fuel, where emissions control is less of a concern. The external design of the tank makes it less expensive to construct and maintain than IFRTs, as it does not require complex internal components.

However, EFRTs are more susceptible to fire and explosion than IFRTs, as the floating roof does not provide as much protection against ignition sources. The roof can also be damaged by high winds or heavy snow loads, which can lead to leaks and spills.

Key Difference

The key difference between IFRTs and EFRTs is the location of the floating roof. In an IFRT, the floating roof is located inside the tank, while in an EFRT, the floating roof is located on top of the tank. This difference in location has several implications for the design, construction, and operation of the tanks.

One of the main advantages of IFRTs is their superior emissions control. The floating roof reduces the amount of vapor space in the tank, which in turn reduces the amount of hydrocarbon emissions that are released into the atmosphere. IFRTs are also less susceptible to fire and explosion, as the floating roof acts as a barrier between the liquid and the air above.

On the other hand, EFRTs are less expensive to construct and maintain than IFRTs, as they do not require complex internal components. EFRTs are also more versatile, as they can be used for storing a wide range of liquid hydrocarbons, including crude oil, diesel fuel, and heavy fuel oil.

Conclusion

Both IFRTs and EFRTs have their strengths and weaknesses, and the choice of tank type will depend on the specific needs of the application. If emissions control is a critical concern, IFRTs are the better choice, as they provide superior vapor control and fire protection. However, if cost and versatility are the top priorities, EFRTs are the better choice, as they are less expensive to construct and maintain and can be used for a wide range of liquid hydrocarbons.

As with any storage tank, proper maintenance and inspection are critical to ensuring safe and reliable operation. Regular inspection of the tank’s components, including the floating roof, pontoons, rim seal, and foundation, is essential to detect and repair any damage or wear before it becomes a safety hazard.

In conclusion, understanding the key differences between IFRTs and EFRTs is important for anyone working in the oil and gas industry. By choosing the right type of tank for the application and maintaining it properly, you can ensure safe and efficient storage of liquid hydrocarbons