As an owner or operator of bulk liquid storage facilities, you need Robust and Resilient Aboveground Storage Tanks that are durable, low-maintenance, and able to withstand the test of time. Aboveground storage tanks (ASTs) are an ideal choice for long-term storage needs. ASTs are engineered to endure exposure to environmental elements and contain a wide range of chemicals for 10 years or more without compromising structural integrity or product quality.

ASTs are also highly customizable to meet specific capacity and containment requirements. Single and double-walled tank options are available along with a variety of linings and coatings to suit chemical compatibility needs. ASTs can be fabricated from stainless steel, carbon steel, aluminum, and fiberglass to provide ideal properties for different operating conditions and budgets.

With minimal maintenance, ASTs continue providing safe and code-compliant storage for the lifetime of the facility. As a robust and resilient solution, ASTs give you confidence in knowing your liquid products and processes are supported by stable, long-term infrastructure. For storage you can depend on for the long run, ASTs are the superior choice.

Choosing a Durable Aboveground Storage Tank

Choosing a durable aboveground storage tank is critical for long-term use. When selecting a tank, consider factors like the material, coatings, foundations, and containment.

The most robust materials are carbon steel, stainless steel, and reinforced concrete. Carbon steel tanks with special polymer coatings that protect against corrosion are a popular, cost-effective choice. Stainless steel tanks are naturally corrosion-resistant but more expensive. Reinforced concrete tanks can last 50-100 years.

For coatings, consider epoxy, polyurethane, and enamel paints which provide an anti-corrosive barrier. Fiberglass-reinforced plastic can also be used as a coating and provides insulation. Regular inspections and touch-up of coatings help maximize tank lifespan.

A proper foundation, like concrete saddles, helps distribute the weight and prevents the tank from settling unevenly. Concrete ring wall foundations are ideal for larger tanks. Proper anchoring to foundations prevents tank movement during environmental events.

Secondary containment, such as dikes and basins, helps prevent spills from contaminating the surrounding area. Containment should hold 110% of the tank’s capacity.

With routine inspections and maintenance, the appropriate tank and coating for your needs, a solid foundation, and secondary containment, an aboveground storage tank can provide safe and durable storage for decades. The initial investment in a high-quality tank pays off through longevity, reduced repairs and replacement costs, and safer operations. By choosing wisely and maintaining properly, your tank can remain resilient and robust for the long term.

Proper Installation and Anchoring for Maximum Stability

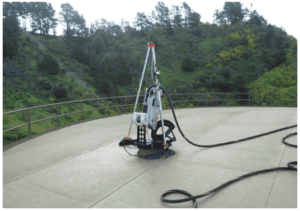

To ensure maximum stability and longevity of your aboveground storage tanks, proper installation and anchoring are essential.

Secure Foundation

A solid foundation provides critical support for your tanks. Pour a concrete pad at least 6 inches thick as a base, extending at least 2 feet around the perimeter of the tank. The pad should be level for optimal stability. For larger tanks, you may need to use a thicker concrete foundation, steel reinforced base, or concrete pillars.

Robust Anchoring

Anchor your tanks to the foundation to prevent tipping or shifting, especially in areas with loose soil or frequent severe weather. Anchor straps, also known as hold-down straps, securely fasten the tank to the concrete base. For rectangular tanks, use a minimum of two straps on opposite corners. Circular tanks require a minimum of four evenly-spaced straps.

Resilient Connections

Double-walled tanks provide an additional level of protection. The space between the walls can be monitored for leaks. All pipe connections and fittings should be properly welded or flanged to prevent corrosion and ensure strength. Gaskets, bolts, and sealants should be constructed of weather-resistant materials.

Regular Inspections

Conduct routine inspections of your aboveground storage tanks and surrounding equipment. Check for signs of damage, shifting, or leakage and make necessary repairs immediately to avoid environmental issues or safety hazards. With proper installation, anchoring, and maintenance, aboveground storage tanks can remain robust and resilient for decades.

By following best practices for installation, anchoring, and inspections, you can count on your aboveground storage tanks to securely contain materials for the long term. Their durability and longevity make them a wise investment for any operation with fluid or chemical storage needs.

Routine Inspections and Maintenance to Ensure Longevity

To ensure the longevity and durability of aboveground storage tanks, routine inspections and maintenance are essential. Inspections should be performed on a regular schedule by trained professionals. They will check for any signs of damage, corrosion or leaks that could impact the integrity or safety of the tank.

Some key areas inspectors will evaluate include:

- The tank shell and welds for any dents, cracks or holes. These could allow hazardous vapors to escape or enable water to enter the tank.

- The condition of the paint or coating and any areas where it has chipped or worn away. Exposed metal will corrode over time.

- The tank foundation and supports. Any damage or deterioration here could compromise the stability of the entire tank structure.

- All valves, pumps, piping, gages and other components. Malfunctioning or leaking parts must be repaired or replaced immediately.

- The containment dike or barrier. Any damage could allow chemicals to leak into the surrounding area.

To complement routine inspections and maintenance helps prevent issues and keeps tanks running safely and efficiently. This includes:

- Repainting or re-coating tanks on a regular schedule, typically every 3 to 5 years for most environments. New coatings protect the underlying metal from corrosion.

- Lubricating and exercising valves and pumps to prevent them from sticking or failing.

- Calibrating gages and meters to ensure accurate readings.

- Testing emergency equipment like flame arrestors, pressure relief valves and vapor recovery systems.

- Performing any necessary repairs, part replacements or tank modifications as recommended by inspectors.

Establishing and following a comprehensive inspection and maintenance plan can maximize the longevity and resilience of aboveground storage tanks. With proactive management and care, these tanks can remain robust and durable for many years, even decades. The benefits of risk reduction, environmental protection, and business continuity far outweigh the nominal upfront investments in time and money.

FAQs:

Common Questions About Aboveground Storage Tanks

What is the typical lifespan of an AST?

Properly installed and maintained ASTs can last 20-30 years or more. The tank material and coatings, environmental factors like UV exposure and humidity, and frequency of use are some of the main factors that determine AST longevity. Steel ASTs with high-quality coatings and cathodic protection in moderate climates may last 30-40+ years. ASTs storing chemicals may have a shorter lifespan of 15-25 years depending on the properties of the chemicals.

How can I maximize the lifespan of my AST?

Several best practices can help maximize AST lifespan:

- Choose a high-quality tank material like carbon or stainless steel and appropriate coatings for your application. Epoxy or enamel coatings and cathodic protection help prevent corrosion.

- Install containment structures to shield the tank from environmental exposure. Containment also provides secondary containment in case of leaks or spills.

- Establish a regular inspection and maintenance schedule to check for signs of wear or damage. Look for corrosion, dents, or holes and repair or replace components as needed.

- Avoid overfilling the tank, which can cause structural damage over time. Do not exceed the maximum filling level.

- Choose a tank material and coatings compatible with the specific chemicals being stored for chemical applications. Some chemicals may corrode certain metals.

- Repair or replace tank components like valves, piping, vents, or containment structures when needed to avoid damage to the tank.

- Consider tank re-coating or replacement once coatings start to significantly deteriorate. New coatings or tank replacement may extend the lifespan by 10-15 years.

- Limit environmental exposure like UV radiation or extreme heat when possible. Containment or shelter structures can help shield the tank.

By following recommended operating and maintenance procedures, AST owners and operators can expect many years of safe and reliable storage from their aboveground tanks. Let me know if you have any other questions!

Conclusion

After considering the full range of options for storing hazardous materials onsite, aboveground storage tanks emerge as the optimal choice for long-term durability and safety. Their robust and resilient double-wall construction provides unparalleled protection against leaks and spills. With proper maintenance and inspection, these tanks can last for decades without issue. While underground tanks may seem convenient, their hidden nature makes monitoring for corrosion and structural failures difficult and the remediation of any issues costly and complex. For peace of mind and regulatory compliance, aboveground storage tanks give you full visibility and control over your storage needs for years to come. For safe, responsible, and sustainable storage of hazardous materials, aboveground tanks are the clear solution.