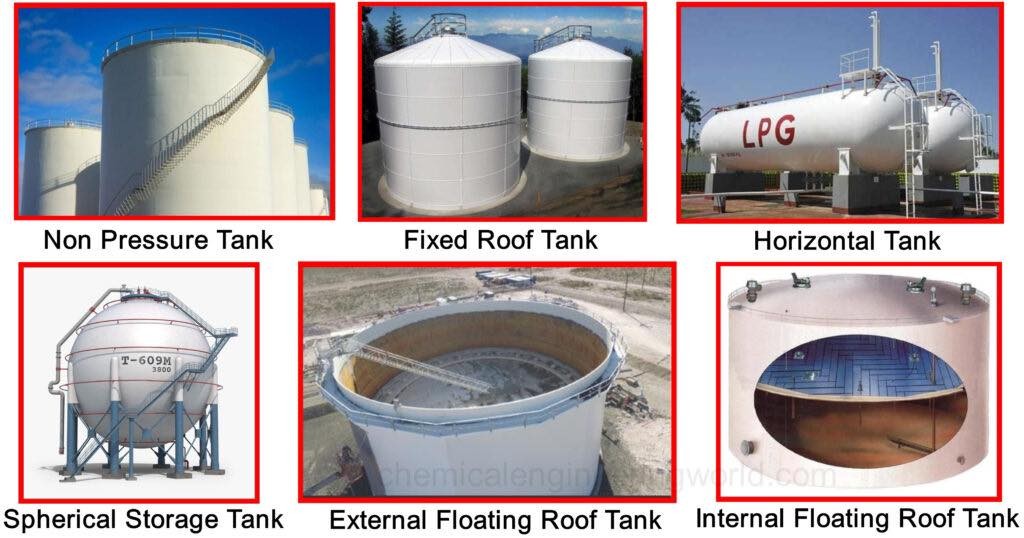

Storage tanks are essential in various industries, including oil and gas, chemical, and water. They store materials such as liquids, gases, and solids in large quantities. Storage tanks come in different sizes and shapes, and they are made from different materials. This article discusses the various types of storage tanks, including industrial storage tanks and aboveground storage tanks.

Types of Industrial Storage Tanks

Industrial storage tanks are used in industries such as oil and gas, chemical, and water. They are designed to store materials in large quantities and withstand harsh environments. The following are the types of industrial storage tanks:

Cone Roof Tank

The cone roof tank is a cylindrical tank with a cone-shaped roof. It is used to store liquids that have high vapor pressure, such as gasoline and diesel. The cone-shaped roof allows the vapor to escape easily, preventing the tank from bursting

- Material selection: Materials commonly used for constructing cone roof tanks, such as carbon steel, stainless steel, or aluminum alloy.

- Design specifics: Describe the design elements that set cone roof tanks apart from other types of storage tanks, such as their sloped roofs that prevent water or snow accumulation and enable natural ventilation.

- Size and capacity: Typical dimensions and storage capacities of cone roof tanks, which may range from small to very large capacities.

- Industries and applications: Various industries (e.g., oil and gas, chemical processing) where cone roof tanks can be used and their specific applications within those industries.

- Advantages and disadvantages: Provide a balanced evaluation of the benefits and drawbacks of using cone roof tanks compared to other storage solutions.

- Maintenance and inspection: Proper maintenance practices can be employed to ensure long-term efficacy and prevent hazardous conditions.

- Regulations and standards: Discuss any applicable regulatory requirements or industry standards that pertain to the design, construction, and operation of cone roof tanks.

Floating Roof Tank

Floating roof tanks are cylindrical tanks with a floating roof that rests on the surface of the liquid. They are used to store liquids that have a low flash point, such as crude oil and gasoline. The floating roof with roof seals reduces the amount of vapor that escapes from the tank, preventing explosions.

Open Top Tank

An open-top tank is a cylindrical tank with an open top. It is used to store materials such as water, chemicals, and food products. The open top allows easy access to the contents of the tank, making it easy to clean and maintain.

- Materials and construction: Describe the materials typically used to construct open-top tanks, such as stainless steel, fiberglass, or plastic. Emphasize the importance of choosing the right material based on the intended use and chemical compatibility.

- Design features: Discuss the design characteristics of an open-top tank, such as its cylindrical shape, flat or sloped bottom, and size options. Also, mention any optional features like agitators, heating or cooling systems, or internal linings.

- Advantages: Explain the benefits of using an open-top tank, including easy access for cleaning and maintenance, flexibility for various process conditions, and efficient heat transfer.

- Disadvantages: Address potential downsides of using an open-top tank, such as increased evaporation or contamination risks due to the lack of a fixed cover.

- Applications: Provide a few examples of industries or processes where open-top tanks are commonly used, such as wastewater treatment plants, chemical manufacturing operations, or food and beverage production.

- Safety considerations: Mention important safety guidelines when working with open-top tanks, such as proper ventilation requirements to prevent the buildup of hazardous gases and appropriate measures to prevent spills or leaks.

Types of Aboveground Storage

Aboveground storage tanks are used to store materials on the surface of the ground. They are commonly used in industries such as agriculture, oil and gas, and chemicals. The following are the types of aboveground storage tanks:

Horizontal Tank

Horizontal tanks are cylindrical tanks that are placed horizontally on the ground. They are used to store materials such as oil, water, and chemicals. The horizontal design allows for easy access to the contents of the tank, making it easy to clean and maintain.

Vertical Tank

Vertical tanks are cylindrical tanks that are placed vertically on the ground. They are used to store materials such as water, chemicals, and fuel. The vertical design allows for more storage capacity in a smaller footprint.

Skid Tank

A skid tank is a small aboveground storage tank that is placed on a skid. It is used to store materials such as fuel and chemicals. The skid allows for easy transport and placement of the tank.

Conclusion

In conclusion, storage tanks come in different sizes and shapes, and they are made from different materials. Industrial storage tanks are used in industries such as oil and gas, chemicals, and water, while aboveground storage tanks are used to store materials on the surface of the ground. It is important to choose the right type of storage tank for your industry to ensure the safety of your workers and the environment.